|

Infrastruktura - Środowisko - Energia

Dodatek lobbingowy do "RZECZPOSPOLITEJ".

9 września 2008 r.

po polsku

The possibilities of design and production of the Polish production base

New machinery for brown coal mines

An interview with

Maciej Przybyła, the President of the FUGO S.A. Konin company, and

Norbert Wocka from SKW Zgorzelec

How - if at all - is Polish industry prepared to provide the future Legnica brown coal mine with machinery and is it able to satisfy the requirements of this process?

Since 1980 domestic coal brown industry has not imported a single excavator or a single drive. Total demand of mines has been met by domestic supply. Poland belongs to a small group of few countries in the world which are self-sufficient in the construction of these machines. The group of leading companies providing technical base include, among others, the FUGO S.A. company in Konin, the FAMAK S.A. company in Kluczbork and the SKW Biuro Projektowo-Techniczne Sp. J. (a construction-design company) in Zgorzelec.

In recent years machinery and devices for brown coal mines have been constructed for both Poland and foreign countries. Taking into account the technical aspect, by no means are these products worse than those manufactured by reputable companies of the world. These achievements prove that Polish economy, taking advantage of its potential, is able to develop a new region of mining and power production, based on brown coal; and - what is more - it is able to do it by itself. A good example here can be bucket-wheel excavators of the KWK series of types, designed and constructed by Polish engineers. KWK-1200 and KWK-1500 excavators have been successfully working in mines. Recently, a KWK-910 excavator for the exploitation of hard diggable formations has been introduced in the BOT KWB Turów brown coal mine.

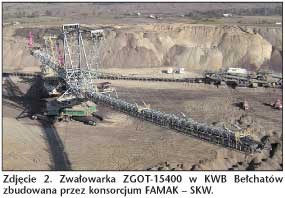

Polish designers have created a very successful series of types of spreaders of the ZGOT-6300, ZGOT-11500 and ZGOT-15400 series. Such spreaders provide a competitive offer for the German ones, which are considered by experts to be the best in the world. The largest of them is the ZGOT-15400 spreader (picture 2), which has been created for the KWB Bełchatów brown coal mine by the consortium including the SKW Zgorzelec company and the FAMAK S.A. Kluczbork company. It is the largest self-propelled machine produced in Poland so far, and it is based on the domestic technical thought. When spread, it is 220 m long, 55 m high, and it weighs ca 3,600 t. The spreader has won general recognition and has been awarded numerous prestigious awards and prizes, both in Poland and abroad (the First Prize of NOT, the Polish Federation of Engineering Associations, for the year 2005; the title of "the Designer of the Year 2006"; recognition of foreign technical magazines, such as American Design News).

Another example of how competitive Polish industry is in that business may be the fact that Polish companies have won international tenets (SKW in terms of the project and FUGO S.A. as a producer) concerning the deliveries of transport crawlers to one of the Greek mines as well as the modernization of 5 excavators in Bulgaria.

What can be the reason for considerable difficulties in completing such tasks as providing the KWB Legnica or KWB Gubin brown coal mines with machinery? It is, after all, several dozen thousand of tons of machinery and devices?

First of all - time. In order to complete such a task competently, the production processes have to be preceded by gaining knowledge of the situation and making some preparation well in advance. Nearly 1/3 of the realization time is required for design and structural work, which, however cheap, are very time-consuming. It is necessary, therefore, to start some preceding design work, before the final approval confirming that the investment will be carried out. A first excavator of a daily production capacity of ca 130,000 mc3 can be put into service within the period of 4-5 years, counting from the date of design work beginning; or within the period of 3 years if the design documents required for the beginning of excavator production are ready.

The production and design base which exists in this business has already developed its own numerous solutions; to what extent can they be used?

Every newly opened brown coal mine operates on a new deposit, characterised by diverse mining and geological conditionings which determine, among other things, also the solutions concerning machinery design. The structure of excavators, spreaders and conveyor belts each time has to take the specificity of the new deposit into account.

Besides, it seems justifiable to take into consideration both the technical progress and the experience of the past 30 years in creating new design solutions; however, these solutions can be based on invaluable exploitation experience which in this business is the factor determining whether you are successful or not.

We are deeply convinced that the existing solutions can either be used themselves or can be taken into consideration while developing the new ones.

The brown coal business is one of the few industrial businesses in the country which has proved its ability to complete whole enterprises related to opencast mine construction; what is more, it is almost exclusively the domestic industry which is involved in such activity. This means thousands of new employment places in the country, not only during the construction work but also after its completion. Polish design thought as well as the equipment based on it are used and function in a lot of countries of the world.

To sum up, it should be emphasised that Poland as a country has got all attributes, such as the scientific and design base as well as companies providing the technical base, and, last but by no means least, considerable experience in maintenance and modernization of "old" bucket-wheel excavators and spreaders as well as in the construction of new ones. For the successful development of the brown coal business in Poland - i.e. to double brown coal output to the level of 120 million Mg per year within the period of 30 years - the new power Policy as well as a governmental programme for the construction of new brown coal mines are necessary. The programme should consider new investments in both time and place. For the accepted Programme Polish brown coal technical base is fully prepared to meet the great challenge of creating new Polish mines and equipping them with Polish machinery and devices. It is the following FUGO Capital Group companies which, together with other companies of the technical base, determine the largest production and design possibilities of our industry related to the brown coal business: the FUGO S.A. company in Konin, the FAMAK S.A. company in Kluczbork, the Fugo Odlew Sp. z o.o. company in Konin, and the closely co-operating Biuro Projektowo-Techniczne SKW (a construction-design company) in Zgorzelec. The potential of this industry guarantees both the design and the production of modern series of types of machinery and devices for new brown coal mines in Poland.

Thank you for the interview.

EM

www.fugo.com.pl

www.skw.pl

|